Welcome to Stresscraft Ltd

We provide a residual stress measurement service using the strain gauge centre hole drilling method. With over 35 years of experience, we have installed, drilled and processed over 60,000 strain gauges. Our customers include universities, research organisations and manufacturers of aero-engines, aerospace components, turbochargers, diesel and racing engines, pressure vessels, pipelines and valve components.

Centre hole drilling is one of the more widely used methods used for residual stress measurement:

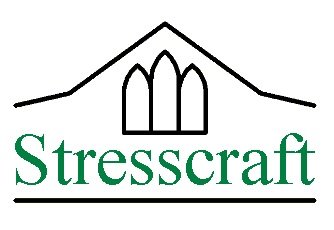

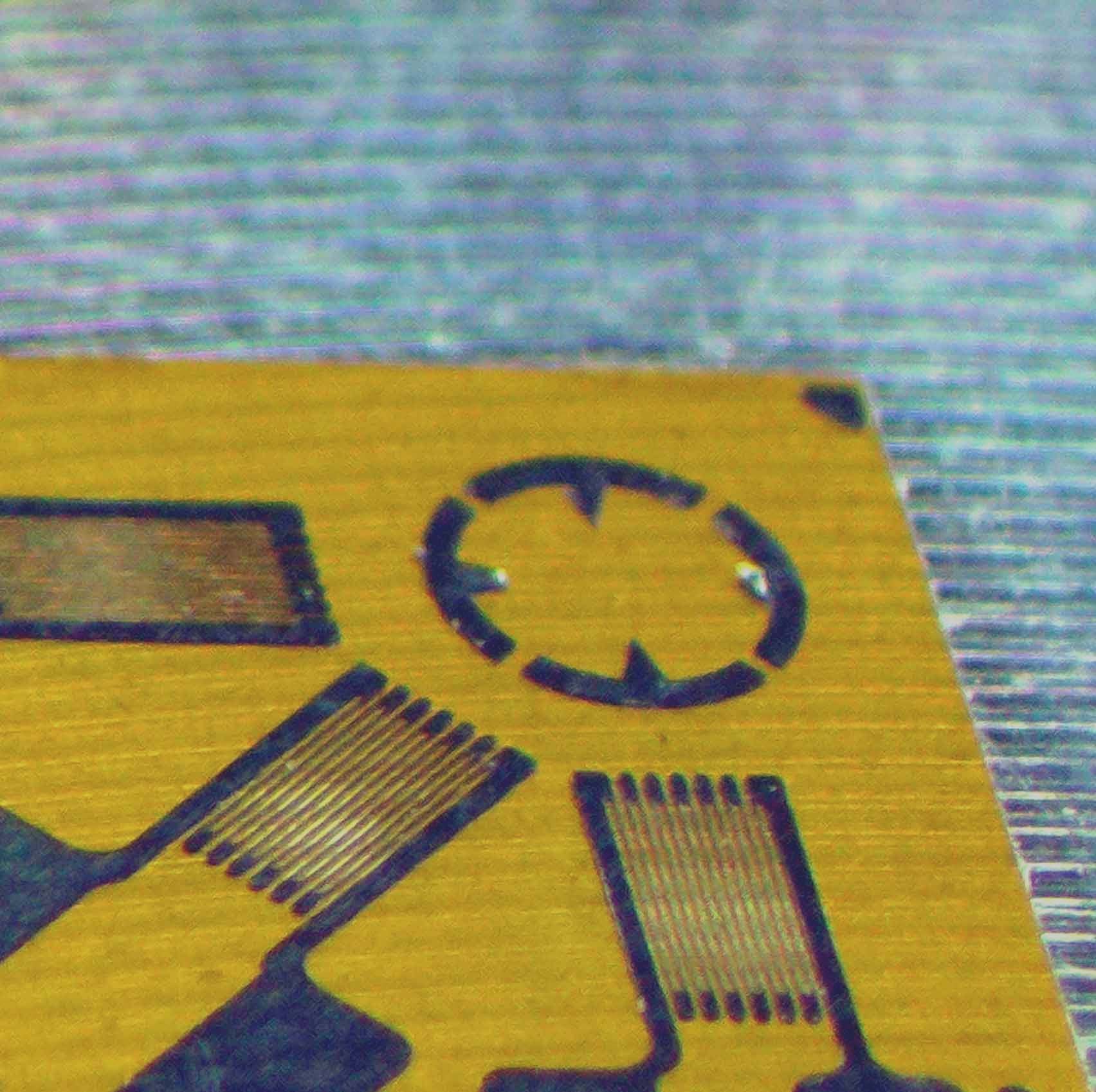

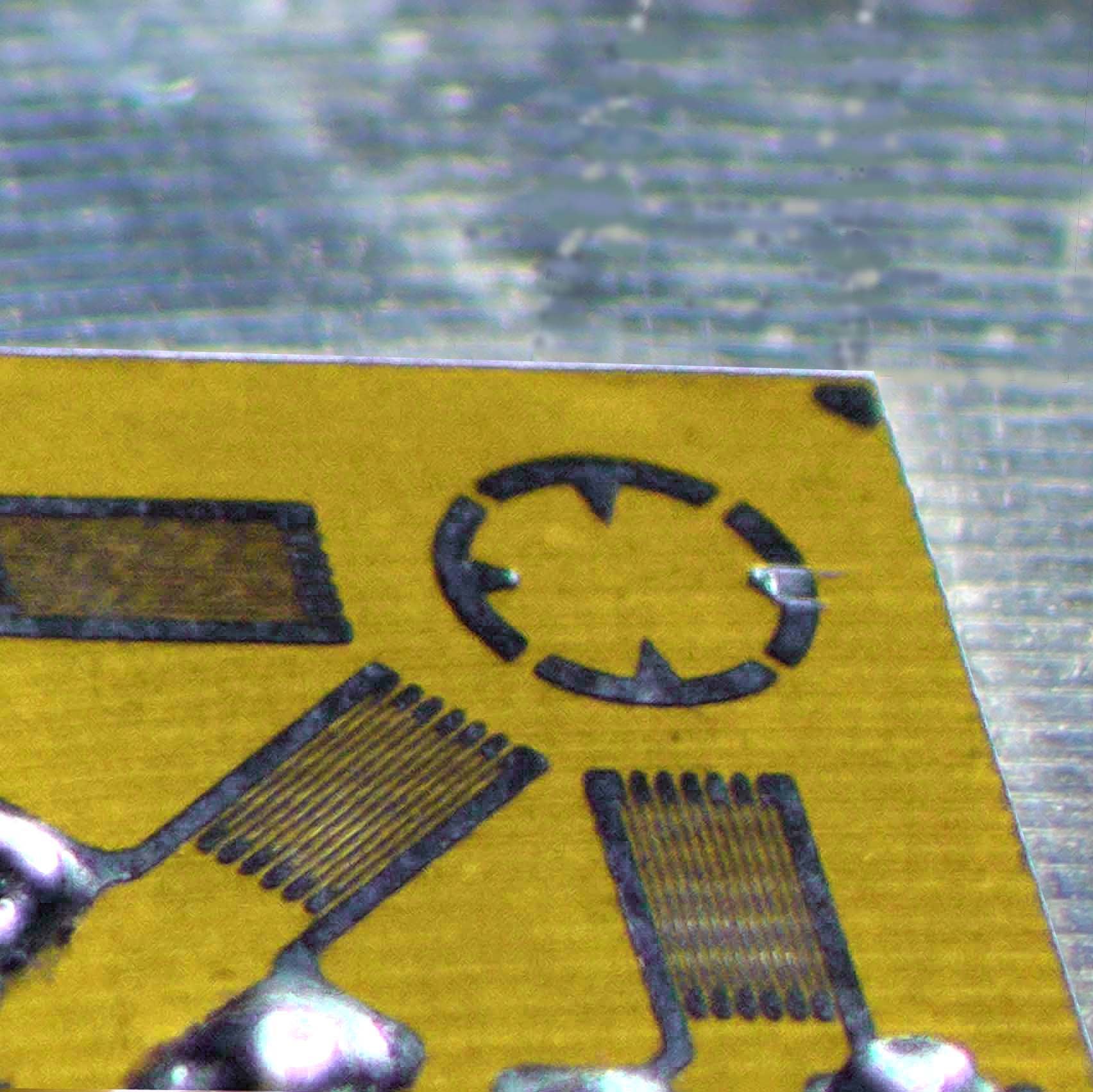

a three element strain gauge rosette is bonded to the component surface and connected to a strain indicator,

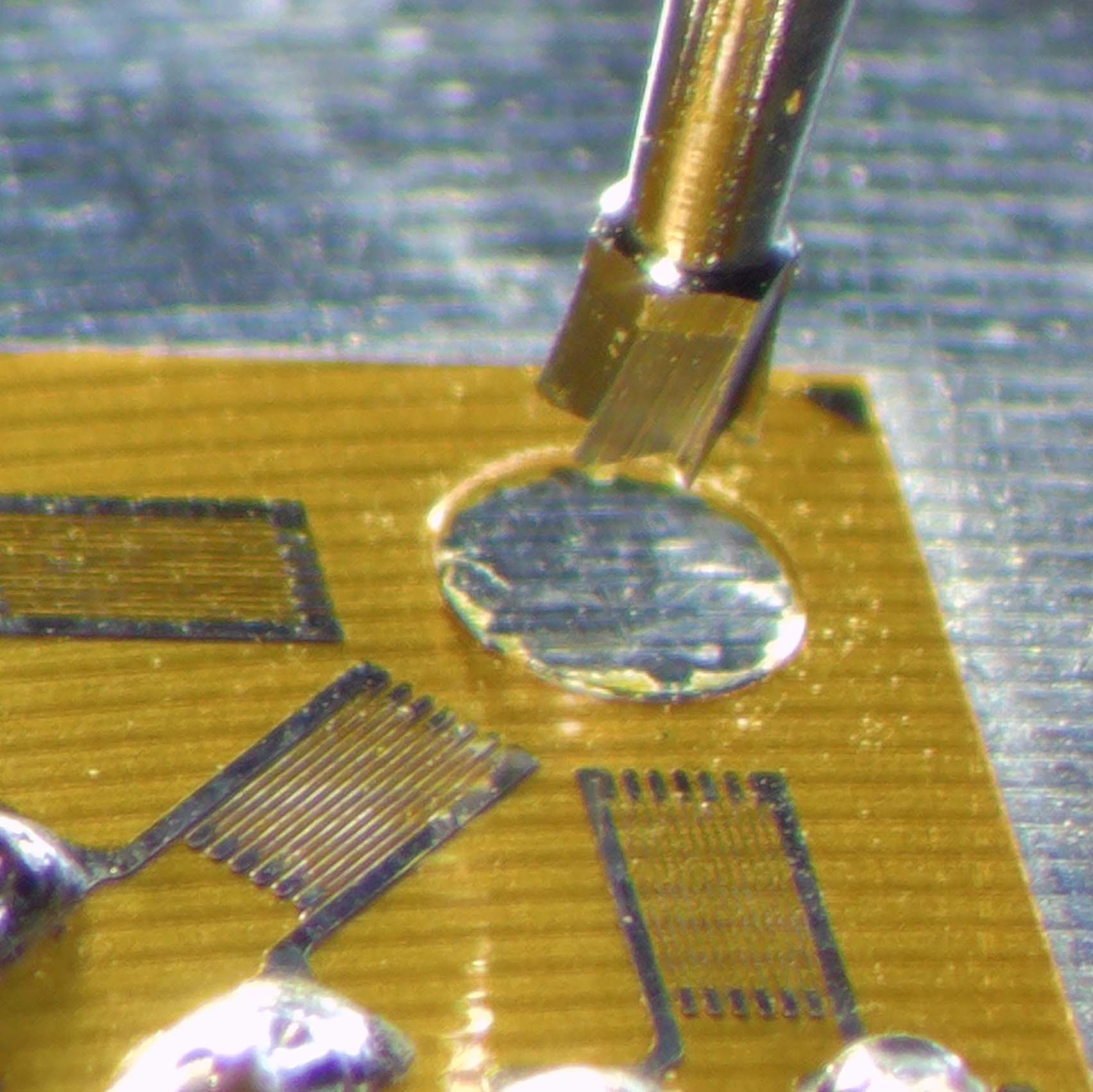

a drilling machine is aligned with the gauge centre and a small hole drilled through the gauge into the component,

drilling proceeds incrementally while strains are recorded at a number of pre-determined hole depths,

after drilling the final increment, the hole diameter is measured,

residual stresses are computed from the relaxed strains, hole diameter and material properties using the Integral Method.

Centre hole drilling at Stresscraft is carried out on components and structures made from a wide variety of materials, including alloy steels, cast-iron, aluminium alloys, nickel super-alloys, titanium alloys, bearing steels, glasses and ceramics. Residual stresses are usually measured to a depth of 0,5 mm, 1 mm or 2 mm, depending on the gauge size and drilled hole diameter. All gauges are drilled using Stresscraft PC-controlled, 3-axis drilling machines with an orbital (circular milling) motion to cut the hole. These machines, in conjunction with a range of straight, right-angle, reverse and offset drill heads provides access to measurement positions in `difficult' locations which would not be possible using conventional drilling machines. The machines and drill heads are all manufactured ‘in-house’; adaptations to the range of drill heads and other equipment expand to suit the requirements of customers’ components and measurement positions. Custom three-element strain gauges have been developed and produced which provide superior performance during installation and operation to enhance the accuracy of the hole drilling method.